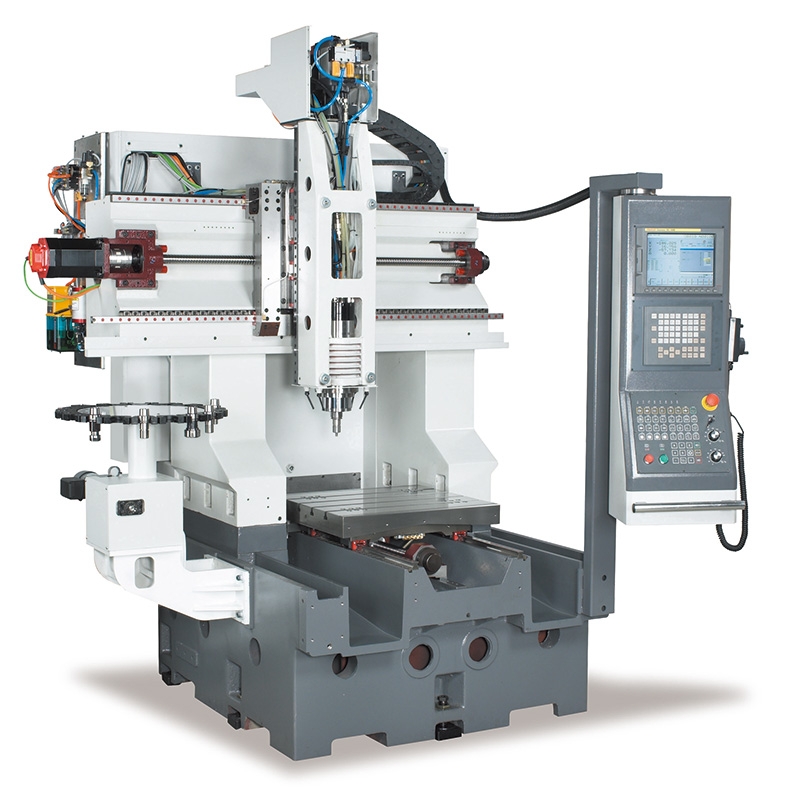

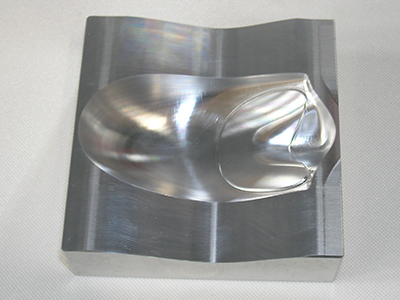

Product Introduction

Feature

Built-in type spindle

- Powerful spindle motor driven by servo system with close loop control can feed-back any cutting condition to spindle motor, achieving to low speed-high torque & high speed–few vibration.

- Offer rigid tapping ability.

- Oil-air lubrication retains stability during high speed and prolong.

- Oil-air lubrication connects with control system closely, and supplies different lubrication depending on different speed.

- 30 minsafter spindle stop running, oil-air lubrication and air protection will shut down, to reduce air consumption ,prolong filter service life ,and avoid oil drop form spindle nose.

Extended large of slide blocks assures cutting rigidity and superior geometric accuracy.

It extends tool life with low vibration behavior.

Roller linear guide way X/Y/Z : 25 / 25 / 25 mm

Ball screw diameter X/Y/Z : 32 / 32 / 32 mm

Easy operation with user friendly interface and easy for loading & unloading of workpiece.

Specifications

| Model | Delta6 | ||

|---|---|---|---|

| Table & Travel | Table Size | mm/mm | 600 x 550 |

| T Slot | No. x W x Pitch | 4 x 14 x 100 | |

| Max. Loading | kgs | 300 | |

| X Axis Travel | mm | 600 | |

| Y Axis Travel | mm | 550 | |

| Z Axis Travel | mm | 360 | |

| Spindle Nose To Table | mm | 150-510 | |

| Feedrate | Rapid Feed | m/min | 30/30/24 |

| Cutting Feed | m/min | 20 | |

| Spindle | Speed (Standard) | rpm | 24000 |

| Speed (Option) | rpm | 30000 / 36000 | |

| Spindle Taper | HSK-E40 | ||

| Power | Kw | 10/13 | |

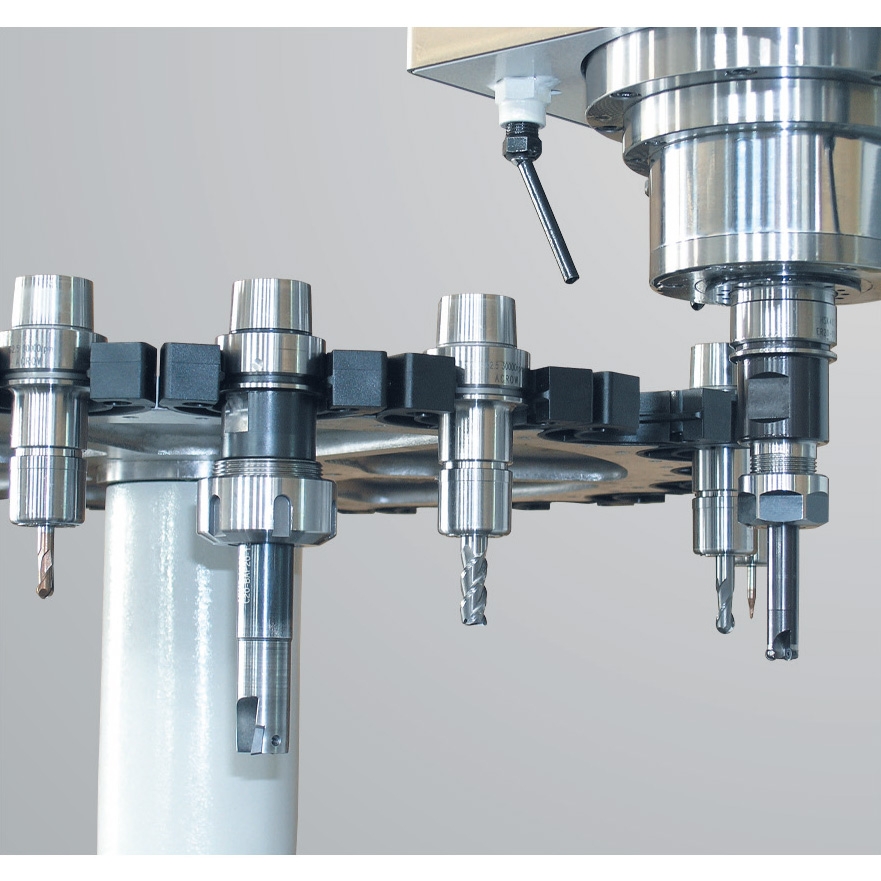

| A.T.C | Tool Shank | HSK-E40 | |

| Tool Capacity | 20 | ||

| Max. Tool Length | mm | 150 | |

| Max. Tool Diameter | mm | 20 | |

| Max. Tool Weight | kgs | 3 | |

| X/Y/Z Servo Motor | X / Y / Z | Kw | 1.6/1.6/1.6 |

| Positioning Accuracy | mm | 0.005 | |

| Repeat Accuracy | mm | 0.004 | |

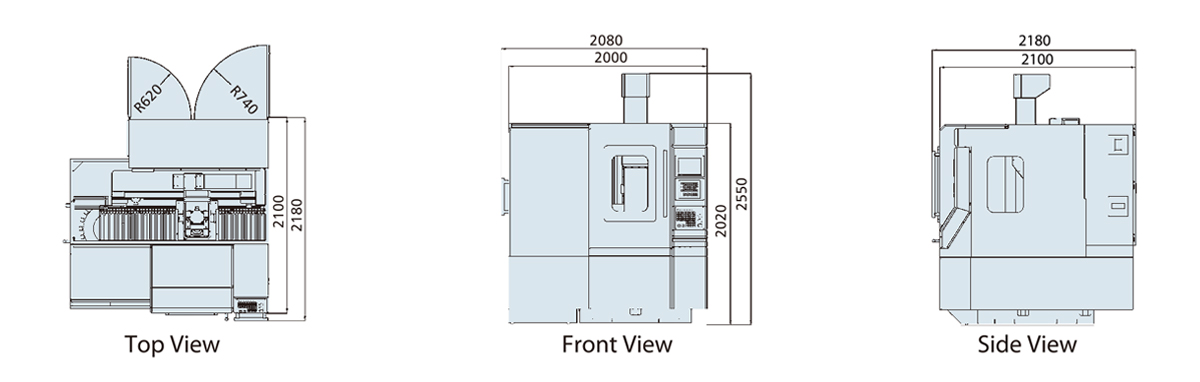

| General | Width | mm | 2080 |

| Depth | mm | 2180 | |

| Height | mm | 2550 | |

| Machine Weight | kgs | 4000 | |

Standard

- Fanuc 0i-MF Plus Controller

- 20T Disc Type ATC

- Full Enclosured Guarding

- Auto Grease Lube System

- Alarm Light

- Working Light

- Spindle Oil Cooler

- Heat Exchanger

- MPG

- Screw Type Chip Conveyor

- Rear Flush System

Option

- Fanuc 31i-MB Controller

- Siemens Controller

- Tool Length Measurement System

- Laser Tool Length Measurement System

- Work Piece Measurement System

- Coolant Through Spindle

- Heidenhain Digital Read Out

- Oil Mist Collector

- Oil / Air Cutting Facility

- Chain Type Chip Conveyor

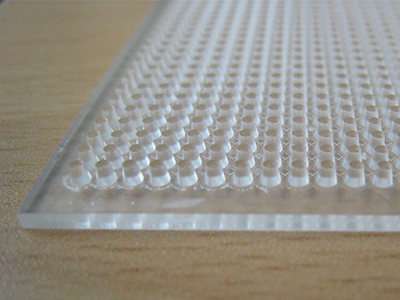

- Graphite Cutting Facility