Product Introduction

Feature

Specifications

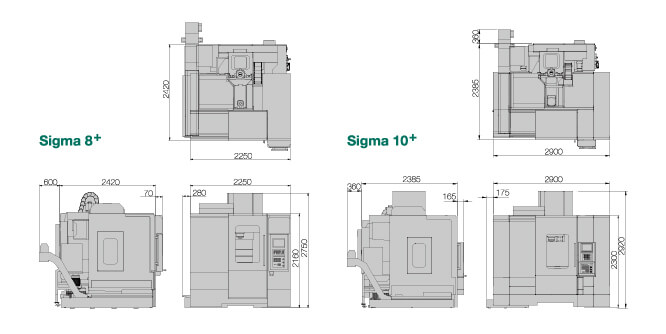

| Model | Sigma 8+ | Sigma 10+ | ||

|---|---|---|---|---|

| Tabel & Travel | Table Size | mm | 1000 x 550 | 1200 x 600 |

| T Slot | mm | 5*18*100 | 5*18*100 | |

| Max. Loading | kg | 600 | 800 | |

| X Axis Travel | mm | 850 | 1100 | |

| Y Axis Travel | mm | 550 | 600 | |

| Z Axis Travel | mm | 600 | 600 | |

| Spindle Nose To Table | mm | 150-750 | 100-700 | |

| Spindle Center To Column | mm | 600 | 655 | |

| Spindle | Spindle Taper | BBT40 | BBT40 | |

| Spindle Taper | BBT40 | |||

| Spindle Speed | rpm (Kw) | 10000rpm (7.5 / 11Kw) | ||

| 12000rpm (11 / 15 Kw) | ||||

| 15000rpm (11/15 / 18.5 Kw) | ||||

| Feedrate | Cutting Feed | mm/min. | 12000 | 12000 |

| X/Y/Z Rapid Feed | M/min. | 36 | 36 | |

| A.T.C | Tool Capacity | 24T ARM | 24T ARM | |

| Max. Tool Diameter*Length | mm | 80*300 | 80*300 | |

| Max. Tool Weight | kg | 7 | 7 | |

| X/Y/Z Servo Motor | X / Y / Z | Kw | 3 / 3 / 3 | |

| Positioning Accuracy | mm | 0.005 | 0.005 | |

| Repeat Accuracy | mm | 0.004 | 0.004 | |

| General | Width | mm | 2530 | 2910 |

| Depth | mm | 3090 | 2710 | |

| Height | mm | 2750 | 2920 | |

| Machine Weight | kgs | 5500 | 6500 | |

Standard

- Fanuc 0i-MF Plus Controller

- 24T ARM Type ATC

- Full Enclosured Guarding

- Auto Grease Lube System

- Alarm Light

- Working Light

- Spindle Oil Cooler

- Heat Exchanger

- MPG

- Screw Type Chip Conveyor

- Rear Flush System

Option

- Fanuc 31i-MB Controller

- Siemens Controller

- 12000rpm direct drive(7.5/11Kw)

- 15000rpm direct drive(15/18.5Kw)

- Tool Length Measurement System

- Coolant Through Spindle

- Oil Mist Collector

- Oil / Air Cutting Facility

- Chain Type Chip Conveyor

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)